3D Printers are capable of printing 3-dimensional objects from virtual digital 3D models, where you can create objects almost of any shape. Solid 3 dimensional objects are created by adding successive layers of material one atop another. 3D printer works on additive manufacturing process in which successive layers of plastic or other materials added one over another in a defined pattern. This manufacturing process is different from traditional subtractive manufacturing process, in which objects are created by cutting away the blocks to give them desired shapes. 3D printing also helps reduce resource wastage.

3D printers has been around for about three decades but in last few years their costs have declined dramatically. There is no complexity in setting up a 3D printer, they can easily be connected with computer like a regular printer and take digital design from computer and make 3D objects. 3D printer can make anything that you can imagine. A student from Texas make a 3D printed gun that can successfully fired a bullet. You can create 3D medical models, clothes, shoes, decorator, jewellery, coffee mug and other objects. 3D printer can transform your ideas into 3-dimensional objects which you can feel in your hands. 3D printers have bright future in medicine, house-building, food, fashion, archaeology and building military components. Even Nasa tests 3D printers in space that will let astronauts build their own equipment while travelling in space.

3D printers are generally in the interests of hobbyists and developers. This technology is used in jewellery, footwear, industrial design, architecture, engineering, automotive, aerospace, dental and medical industries, education, civil and various other fields. 3D printing is also using in Nano-robot invention.

How actually this technology works? How a digital 3D model transformed into a 3 dimensional solid objects? How a single machine itself give birth to new objects from ideas?

The whole process starts with an idea. First, you have to design an idea in computer system using software program like CAD (computer aided design) or 3D modelling software and second, give a print command to transfer digital 3D model to 3D printer. Thereafter, 3D printer starts its process of additive manufacturing and print solid object.

Designing

This is the process where idea has to design in a 3D modelling software. Software program create virtual blueprints of the model. It creates a standard STF file which contain the data of designed model. Thereafter, design is divided into digital cross-sections that printer can easily take into design process, they are essential to guide printer to print an object.

You can also purchase pre-build designs from the market, can download or hire someone to design for you, there are numerous online design sites.

After, you have created the design and make an exported .STL file, now prep the machine for print.

Printing

There you need the material to fill into the cartridges, the system will automatically feed the material filament to the extrusion head. Once you command the print, printer initiates the pre-build routine. Machine fills the build chamber with a thin layer of powder so that the parts, when finished are easy to remove from the chamber.

There you need the material to fill into the cartridges, the system will automatically feed the material filament to the extrusion head. Once you command the print, printer initiates the pre-build routine. Machine fills the build chamber with a thin layer of powder so that the parts, when finished are easy to remove from the chamber.

The printing process may vary depending on the type of the 3D printer but, technology is same as building the layer one over another until the final product will build. This is a additive process, so successive layer of liquid, powder, paper or other material lays down according to the cross sections from a digital model. The whole process can take several hours to days depending on the complexity of the object.

Printer resolution measures in layer thickness and dpi (dots per inch). This also vary from printer to printer. The layer thickness is around 100 micrometres (0.1 mm).

Additive manufacturing can be faster, more flexible and less expensive for producing small quantity of objects and can be build on a small desktop size printer.

Though, Price of 3D printers decline dramatically but, they still costs around 1000$ for small printer that can print objects like toys and other similar objects or gadgets. But technology is refining day by day so, we could expect 3D printers in the reach of regular customers in near future.

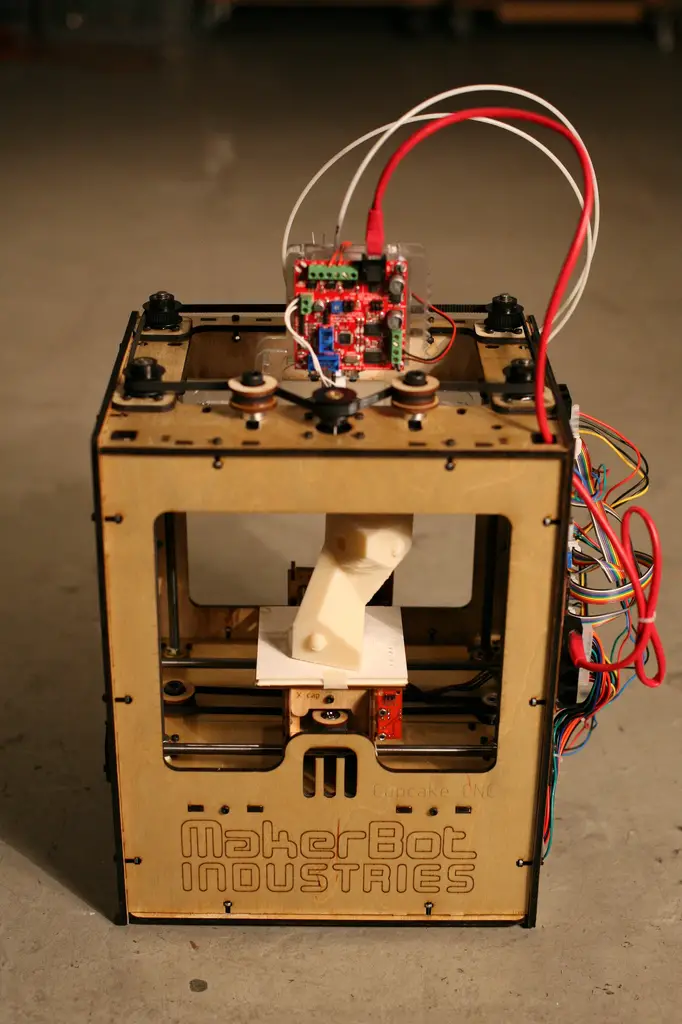

Image: Wikipedia

Comments